Oats are a versatile and nutritious grain that play a staple role in many diets around the world. From your breakfast oatmeal to baked goods, the journey of oats from field to table is an intricate process involving several detailed steps. In this blog post, we will delve into the fascinating journey of how oats are made, exploring key stages such as cleaning, grading, dehulling, drying, milling, rolling and cutting, and finally roasting and packaging. Each step ensures that the oats are of the highest quality before they end up on your table, offering maximum nutritional benefits with a delightful taste.

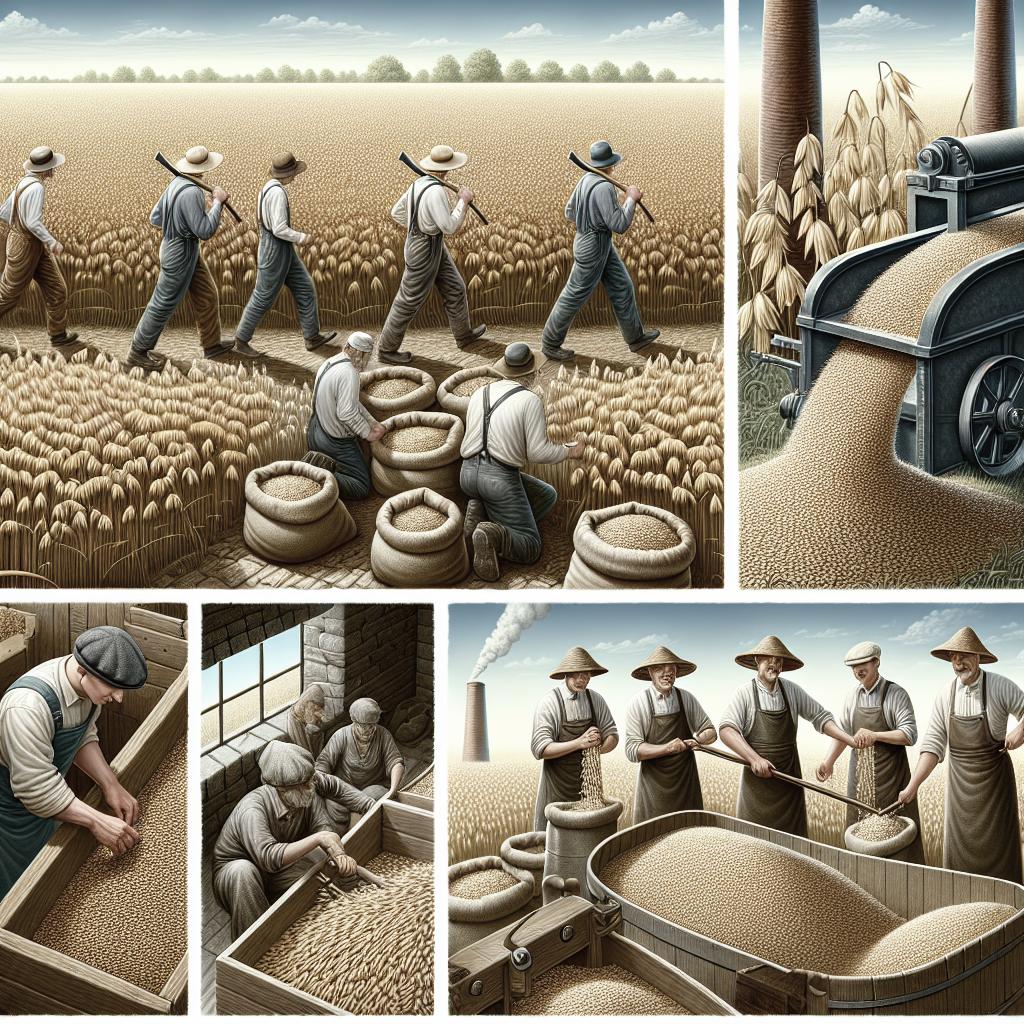

Cleaning, Sifting, and Sorting

The first crucial step in oat processing is cleaning, sifting, and sorting. This process begins as soon as the oats are harvested. At this stage, the oats contain a mixture of other debris such as stones, dirt, and other grains. Such impurities must be meticulously removed to ensure the purity and quality of the final product. The oats are subjected to a series of mechanical cleaners equipped with screens and blowers. These cleaning machines sift through the masses, separating the oats from foreign materials based on size, shape, and density. Additionally, magnets may be used to attract and remove any metallic fragments. This extensive cleaning protocol not only enhances the quality but also ensures that the subsequent processing stages can be carried out efficiently.

Grading

Once the oats are thoroughly cleaned, they are graded. Grading is an important step as it categorizes the oats based on size, weight, and uniformity. This step ensures that the oats are consistent in quality for consumers and appropriate for various forms of oat products. Grading typically involves passing the oats through a series of rollers and sieves that sort them according to specific size ranges. Larger, heavier oats are usually set aside for making rolled oats or steel-cut oats, while the smaller ones might be allocated for instant oats or oat flour. This meticulous sorting system guarantees that each type of oat product meets its intended quality standards.

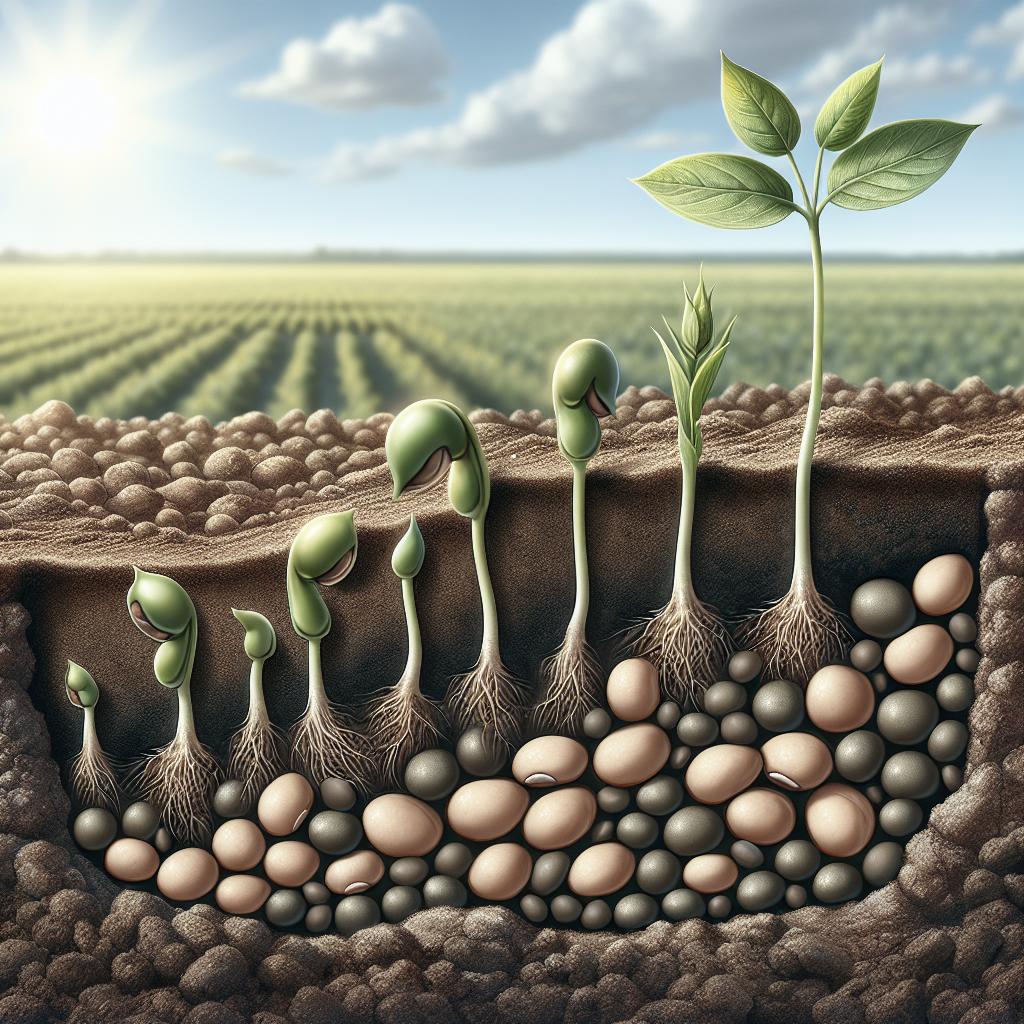

Dehulling

The dehulling process removes the hard, outer hull or husk of the grain, which is inedible. This is a critical step, as it exposes the edible part of the grain—the oat groat—ensuring that the final product maintains its nutritional integrity. Dehulling is often conducted using machines called impact dehullers, which crack the outer shell by applying a forceful impact. The cracked hulls and groats are then separated using air aspirators. This process ensures that the maximum amount of groat is retained while efficiently discarding the inedible hulls. Dehulling must be done carefully to prevent the groats from breaking, which is vital for the quality of the final products.

Drying

After dehulling, the oat groats undergo drying. Drying is a crucial step that reduces the moisture content of the groats, extending their shelf life and preventing spoilage. Drying typically takes place in large heaters or kilns that carefully control the temperature and airflow to evenly dry the groats without compromising their nutritional value. This step not only prepares the oats for further processing but also enhances their flavor and texture. Proper drying is essential for ensuring that oats maintain their quality during storage and transportation.

Milling

Milling is another vital step in oat processing, particularly for producing oat flour. During milling, the dried oat groats are ground into fine oat flour, which can be used for baking, cooking, and more. Various types of mills, such as roller mills and hammer mills, are employed to achieve the desired consistency of oat flour. The milling process often includes sifting to ensure uniform texture and to remove any remaining larger particles. This step is particularly important for ensuring that the oat flour is of the highest quality for culinary applications.

Rolling and Cutting

Rolling and cutting are key processes for producing different types of oat products like rolled oats, quick oats, and steel-cut oats. Each of these processes affects the texture and cooking time of the final product. For rolled oats, the oat groats are steamed to soften them and then passed through large rolling mills to flatten them. This increases their surface area, allowing for quicker cooking times. Quick oats are similar but rolled thinner and cut into smaller pieces. On the other hand, steel-cut oats are produced by cutting the oat groats into several pieces using steel blades. Each method results in a unique texture and cooking time, catering to diverse culinary preferences.

Roasting and Packaging

The final stages of oat processing involve roasting and packaging. Roasting the oats brings out their natural flavors and extends their shelf life. This is done by subjecting the oats to dry heat in large roasters. Once roasted, the oats are cooled and then moved to packaging. Packaging is done in a controlled environment to ensure freshness. Modern packaging techniques often involve vacuum sealing or using inert gases to prevent oxidation and preserve the quality of the oats. The packaged oats are then ready for distribution, ensuring that they reach consumers in peak condition. By understanding these steps, you gain a deeper appreciation for the complex and fascinating journey of oats from field to table.

3 Comments

1. John Doe: “This article really opened my eyes to the complexity behind oat production. Thanks for the detailed information!” 2. Jane Smith: “I never knew there were so many steps involved. Great read!” 3. Harry Brown: “Informative post! Now I know why my morning oats are always so high quality.”

Leave a Comment

Your email address will not be published. Required fields are marked * Name * Email * Website Comment * Post Comment

Related Posts

The Nutritional Benefits of Oats

Different Types of Oats and Their Uses

5 Easy Oat Recipes You Must Try

Summary of main points

| Step | Description |

|---|---|

| Cleaning, Sifting, and Sorting | Removes impurities like stones, dirt, and other grains to ensure purity. |

| Grading | Categorizes oats based on size, weight, and uniformity. |

| Dehulling | Removes the inedible outer hull to expose the edible groat. |

| Drying | Reduces moisture content to extend shelf life and enhance flavor. |

| Milling | Grinds dried oat groats into fine oat flour. |

| Rolling and Cutting | Transforms oat groats into rolled oats, quick oats, or steel-cut oats. |

| Roasting and Packaging | Roasts oats for flavor and shelf life, then packages them for distribution. |