Oats are a beloved staple in many households worldwide. From hearty breakfasts to incorporating them into smoothies and baked goods, their versatility is unmatched. But have you ever wondered how oats arrive at your table? This blog post delves into the intricate process of oat production, from their cultivation in fields to the final products on the grocery store shelves. We’ll explore each step of this fascinating journey, including milling, cleaning, sifting, sorting, grading, dehulling, drying, rolling, cutting, roasting, and packaging. Discover how each step contributes to the nutritional value and delicious taste of oats, and understand how they are transformed into the various forms we consume today.

Milling

The journey of oats begins in the milling process. Milling involves cleaning the harvested oats to remove any debris and foreign materials. The oats are then screened to separate them based on size. This preliminary step ensures that only the finest quality oats proceed further. After initial screening, the oats are sent through a series of machines that separate the hulls from the edible groats. This process requires precision and care, as intact groats are crucial for the next stages. Special mechanical devices gently rub the oats against one another, further separating the hulls and minimizing damage to the groats.

Cleaning, Sifting, and Sorting

Once milling is complete, the oats undergo a thorough cleaning, sifting, and sorting process. This step serves to remove any remaining hull fragments, rocks, or other impurities that may have been missed earlier. Oats are passed through air streams and vibrating screens, which further clean and sort them. Certain machines use gravity tables to distinguish between heavier, quality oats and lighter, inferior particles. The end result is a batch of clean oats free from any contaminants, ensuring that the next steps focus solely on the highest-quality grains.

Grading

Grading is a critical phase where oats are classified based on size, weight, and quality. This classification ensures that each batch of oats meets strict standards before being processed into different oat products. Grading machines equipped with sensors and cameras assess each oat, segregating them accordingly. During this phase, defective oats, such as those with discoloration or deformities, are removed. This quality control measure is essential for producing a uniform final product. Only the best oats proceed to the subsequent stages, guaranteeing consumer satisfaction and maintaining product consistency.

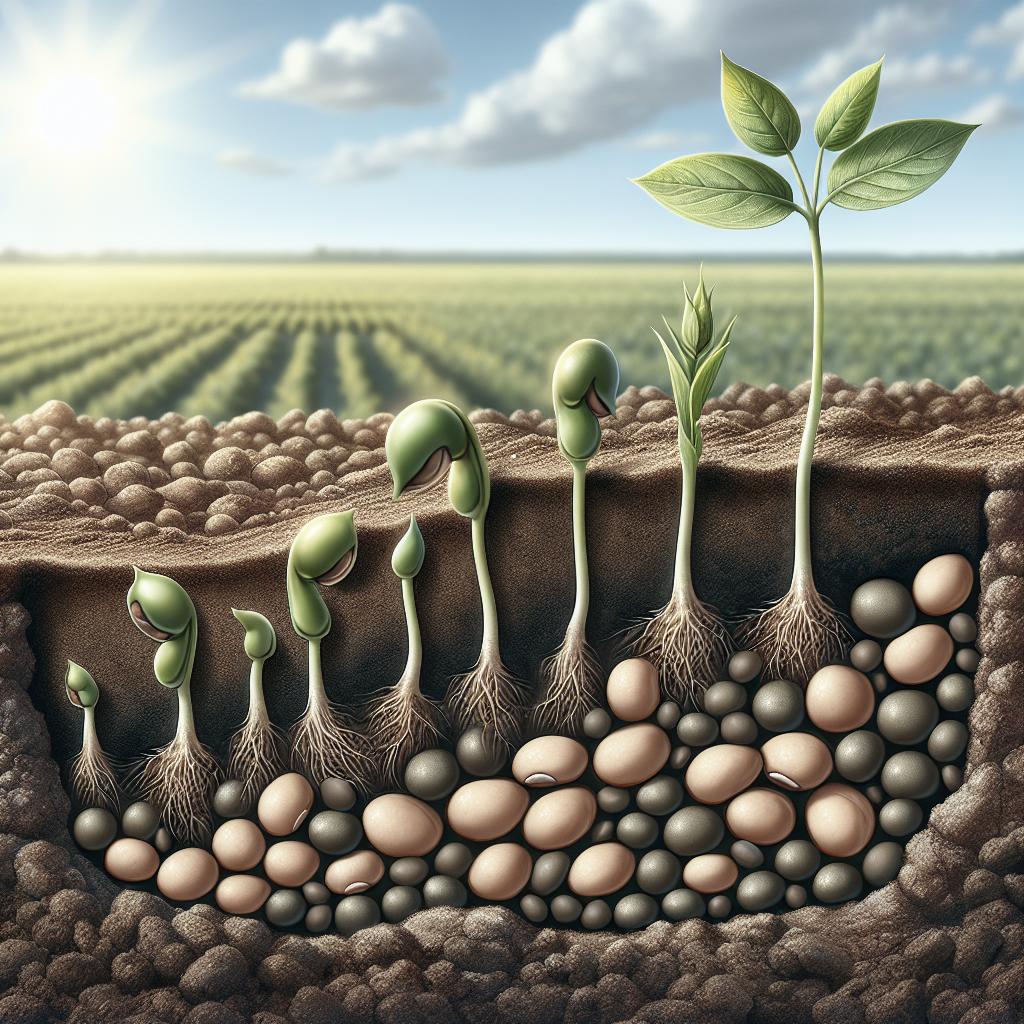

Dehulling

Dehulling is the process where the outer, inedible hull of the oat is removed, exposing the inner groat. This stage is delicate, as it requires breaking the hull without damaging the groat. Machines specifically designed for dehulling apply just enough force to crack the hull while leaving the inner groat intact. The dehulled oats are subjected to additional cleaning to remove any remaining bits of hull. This ensures that the final product is pure and free from any extraneous materials. The now hulled oats are ready to be transformed into the various forms of oats we find in stores.

Drying

Drying is a crucial step in the oat-making process that helps enhance shelf life and prepare the groats for further processing. After dehulling, the oats are subjected to low-temperature drying. This procedure removes the moisture content, which is essential to prevent spoilage and mold growth. The drying process also plays a pivotal role in texture development. By carefully controlling the drying temperature and duration, producers can ensure that the oats achieve the desired texture, whether for whole oat groats, rolled oats, or steel-cut oats.

Rolling and Cutting

Depending on the type of oat product being produced, the dried groats undergo rolling or cutting. For rolled oats, the groats are steamed to soften them before being passed through rolling mills, which flatten them into flakes. This process can be adjusted to create different thicknesses, resulting in old-fashioned oats, quick oats, or instant oats. Conversely, steel-cut oats are made by cutting the whole groats into smaller pieces with steel blades. This method produces a coarser texture that is ideal for people seeking a robust, chewy oat experience. Both rolling and cutting processes contribute significantly to the oats’ cooking time and texture, allowing for a range of oat products to suit various culinary needs.

Roasting and Packaging

Roasting is an optional but popular step that enhances the flavor of oats, adding a nutty, toasty aroma and taste. The oats are exposed to a specific temperature for a set duration, which caramelizes the natural sugars and develops a richer flavor profile. Finally, the oats are packaged. This step is performed in hygienic, controlled environments to prevent any contamination. Packaging materials are selected to maintain the oats’ freshness, protect them from moisture and light, and extend their shelf life. These packaged oats are then ready to be shipped to retailers and eventually find their way to your pantry.

3 Comments

1. Jane Doe : “I had no idea there were so many steps involved in processing oats! Really fascinating read!” 2. John Smith : “Loved learning about the different types of oats and how they’re made. More of these detailed posts, please!” 3. Emily White : “The dehulling process sounds so intricate. Makes me appreciate my morning oats even more.”

Leave a Comment

We would love to hear your thoughts on our oat-making process! Leave your comments below and share your breakfast recipes or oat insights with us.

Related Posts

1. The Nutritional Benefits of Oats 2. Oats in Gluten-Free Cooking: What You Need To Know 3. 5 Delicious Overnight Oat Recipes to Try

Future Prospects

The production of oats is a meticulous process that ensures high-quality, nutritious, and delicious products for consumers. Each step, from milling to packaging, plays a crucial role in transforming raw oats into the versatile food staple we enjoy daily. With advancements in technology and continual improvements in quality control, the future of oat production promises even greater efficiency and innovation. The aim is not only to enhance the quality and variety of oat products but also to maintain their sustainability and affordability for all. Below is a summary table of the steps involved. “`html

| Step | Process | Description |

|---|---|---|

| Milling | Initial cleaning and screening of oats | Removes debris and separates hulls from groats |

| Cleaning, Sifting, and Sorting | Further cleaning and sorting | Eliminates impurities, ensuring clean oats |

| Grading | Classification by size, weight, quality | Ensures uniformity and high quality |

| Dehulling | Removal of the outer hull | Exposes the edible groat |

| Drying | Low-temperature drying | Reduces moisture content, enhances texture |

| Rolling and Cutting | Steaming, flattening, or cutting of oats | Creates different types of oat products |

| Roasting and Packaging | Optional roasting and final packaging | Enhances flavor and readies oats for market |

“`